Ideal Digitizing for Embroidery: Boost Your Tasks

Ideal Digitizing for Embroidery: Boost Your Tasks

Blog Article

Understanding the Embroidery Digitizing Process: Your Ultimate Overview

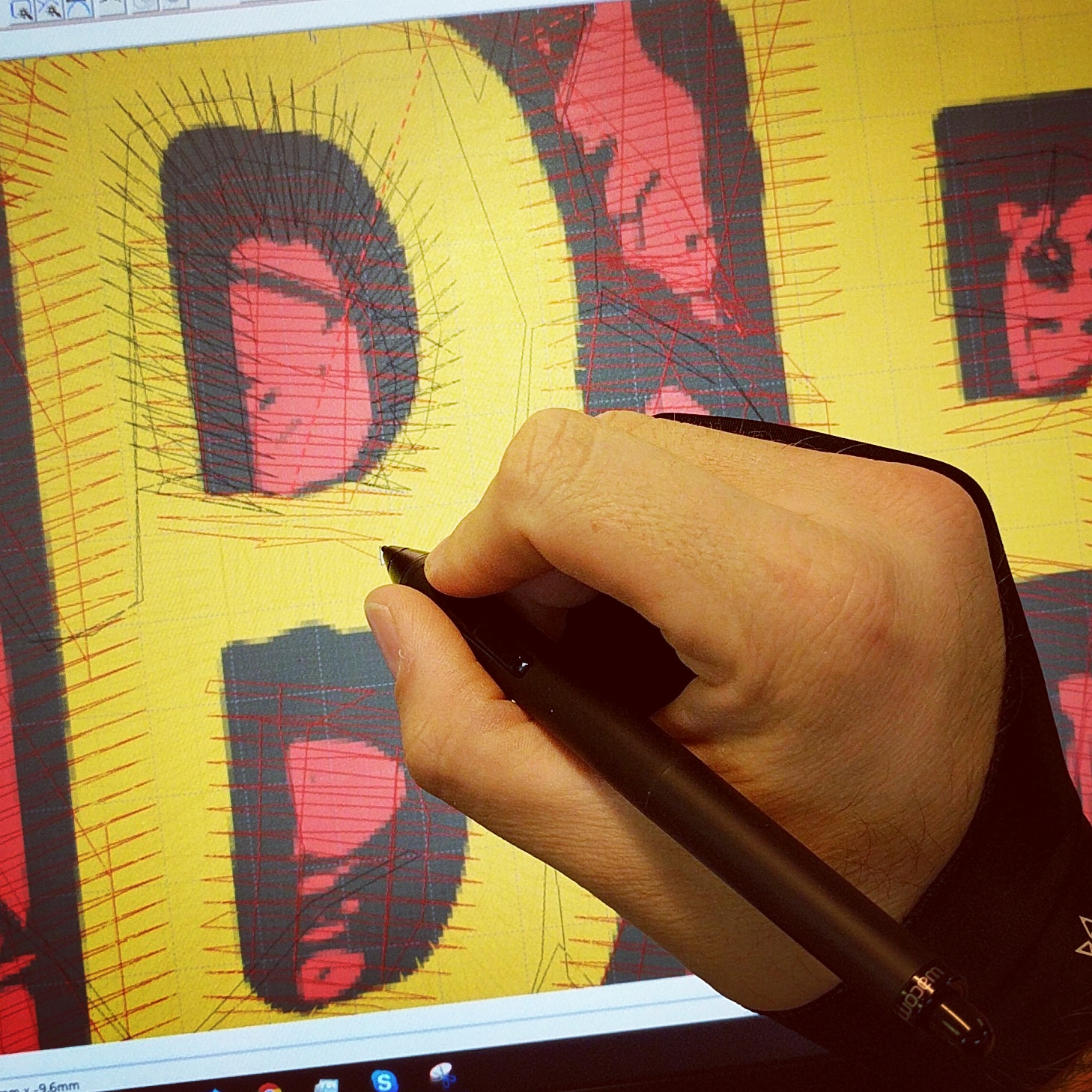

Embroidery digitizing is a thorough craft that requires precision and experience to translate complex designs into electronic layouts for device needlework. As craftsmens embark on this trip to understand the embroidery digitizing process, a thorough understanding of the basics sets the structure for quality. However, beyond the fundamental expertise exists a world of sophisticated software program, specialized devices, and nuanced techniques waiting to be explored. By diving right into the subtleties of digitizing, one can open a globe of imaginative possibilities and elevate their embroidery jobs to new heights.

Comprehending Embroidery Digitizing Fundamentals

Embroidery digitizing fundamentals create the structure whereupon detailed layouts are converted right into machine-readable layouts for specific sewing. This first action in the needlework digitizing procedure is critical for guaranteeing that the final embroidered product is a loyal depiction of the initial style. Comprehending embroidery digitizing fundamentals includes understanding essential concepts such as stitch kinds, sew instructions, density, underlay, and pull compensation.

Sew kinds play a crucial function in identifying the visual and textural end result of the stitched style. By selecting the proper stitch kind, whether it be satin, fill, or running stitch, digitizers can accomplish the desired result and improve the general quality of the needlework. Furthermore, stitch instructions affects the flow and measurement of the style, while density identifies the spacing and coverage of the stitches.

In addition, rug stitching gives security to the design by safeguarding the material and preventing distortion throughout the embroidery procedure. Pull compensation is an additional important factor to consider to combat the natural propensity of fabric to agreement when stitched. Understanding these embroidery digitizing essentials is essential for developing professional-quality embroidered items.

Selecting the Right Digitizing Software

Selecting the proper digitizing software is an important choice that considerably affects the performance and quality of the embroidery digitizing process. Digitizing for Embroidery. When selecting the appropriate digitizing software, it is necessary to take into consideration factors such as the complexity of styles you intend to develop, the user-friendliness of the software program, the level of customer support provided, and the compatibility with your embroidery machine

There are numerous digitizing software program options readily available in the market, varying from basic programs for novices to innovative software for professional digitizers. Some popular choices include Wilcom EmbroideryStudio, Hatch Embroidery Software Program, and PulseID. These software packages supply a broad variety of devices and functions to assist you produce complex styles effortlessly.

Before deciding, it is recommended to explore the different software options with free trials or demos to determine which one best matches your requirements. Furthermore, reading reviews and looking for suggestions from knowledgeable digitizers can offer valuable understandings right into the staminas and weaknesses of each software (Digitizing for Embroidery). By meticulously examining your requirements and contrasting the functions of different digitizing software program, you can make an educated choice that boosts your needlework digitizing workflow

Digitizing Devices and Methods

Optimizing Style Setup for Embroidery

Grasping the ins and outs of style setups is essential in accomplishing ideal results in the embroidery digitizing procedure, building upon the structure laid by recognizing digitizing devices and methods. When enhancing style settings for embroidery, it is vital to consider elements such as stitch type, density, underlay, draw settlement, and enrollment. Stitch type selection affects the total look and feel of the design, with alternatives like satin, fill, and running stitches supplying various structures and impacts. Density describes the spacing and density of stitches, affecting the design's protection and durability. Correct rug stitching provides security and avoids fabric distortion, Related Site specifically for complicated designs or on elastic products. Pull settlement changes for material stretch throughout stitching, guaranteeing exact style replication. Enrollment settings straighten different components of the style accurately, keeping overall layout stability. By fine-tuning these design setups, embroiderers can enhance the top quality and precision of their stitched developments.

Troubleshooting Common Digitizing Issues

When running into typical digitizing issues during the needlework procedure, it is vital to recognize the origin triggers and implement efficient options without delay. One typical trouble is stitch density problems, where stitches might be also dense, creating the material to pucker, or too sporadic, bring about voids in the layout. Changing the stitch density setups in the digitizing software program can assist solve this concern.

Another regular challenge is thread breaks during the embroidery procedure. This can occur due to numerous factors such as incorrect stress setups, plain needles, or using low-quality thread. Ensuring correct maintenance of the needlework equipment, including routine needle changes and stress modifications, can reduce the occurrence of thread breaks.

Additionally, design registration errors can result in misaligned aspects within the needlework design. Inspecting the design positioning in the digitizing software application go and making essential modifications prior to sewing can aid in preventing this issue. By addressing these usual digitizing issues without delay and efficiently, you can ensure a smoother needlework process and top quality completed items.

Final Thought

Finally, grasping the needlework digitizing process needs a strong understanding of the basics, the ideal choice of software program, and understanding of tools and techniques. Enhancing style settings and troubleshooting usual digitizing problems are vital action in ensuring top quality needlework outcomes. By complying with these steps faithfully, one can accomplish precision and effectiveness in the digitizing procedure.

Report this page